THE STRATASYS

OBJET EDEN260VS

DENTAL ADVANTAGE

Production Efficiency for Growing Dental Labs

The Stratasys Objet Eden260VS Dental Advantage 3D printer is the designed to meet the needs of your growing lab. It combines high resolution PolyJet technology with greater speeds and a larger build envelope to promote greater throughput. Give your lab a dental advantage with advanced 3D printing technology.

Give Your Lab an Advantage

Digital dentistry is an industry advancement that is transforming dental lab workflows and creating new opportunities for profitability. The Objet Eden260VS Dental Advantage from Stratasys is the tool that your lab needs to join in this digital dentistry revolution. With twice the build speed of entry-level 3D printers and the production capacity to increase your throughput, the Dental Advantage offers your lab faster turnaround and the lowest cost-per-part through improved automation. Sit back, relax, and let your thoughts wander to the places you’ll go with the Objet Eden260VS Dental Advantage doing the heavy lifting.

Key Features That Drive Productivity

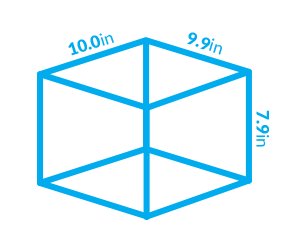

Build Size

The Stratasys Objet Eden260VS Dental Advantage has a maximum print size of 10.0 x 9.9 x 7.9in (255 x 255 x 200mm)

Layer Thickness

Horizontal build layers as fine as 16 microns (0.0006in)

Speed

Twice the build speed of entry-level 3D printing solutions

Greater Capacity

Greater Capacity

Print multiple models in a single run with a larger build tray

Economical

The lowest cost per part through improved automation

Materials

Work with 4 dental specific material types

Advantages of 3D Printing

Streamline In-House Production

Be ahead of the dental industry’s shift into digital workflow by integrating the Objet Eden 260VS Dental advantage into your workflow. With digital files directly from intraoral scans or other CAD/CAM softwares, you can eliminate manual modeling and cut production costs by bringing production in-house.

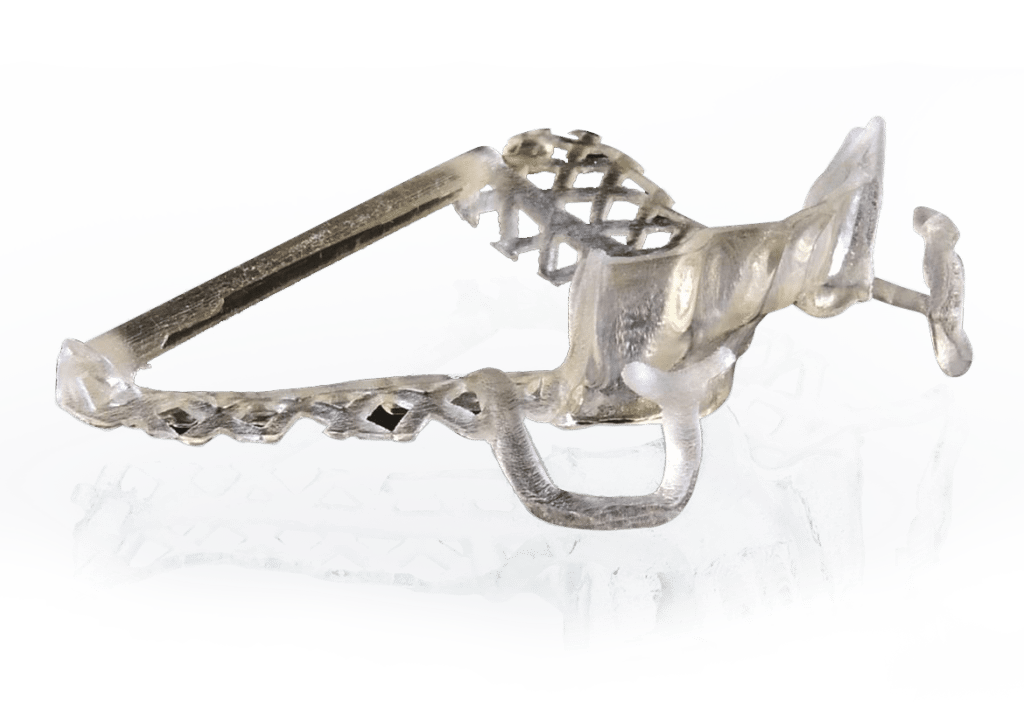

Lower Costs, Increased Production

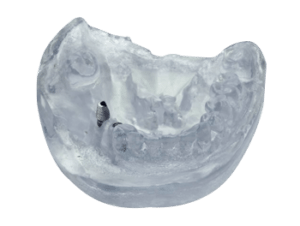

The Stratasys Objet Eden260VS Dental Advantage prints parts directly from digital scan files twice as fast as smaller PolyJet machines. It also uses soluble support material to further simplify the process by dissolving support in tricky areas like tiny crevasses, overhangs or cavities. Through improved automation the Eden260VS delivers the lowest cost per part for growing labs.

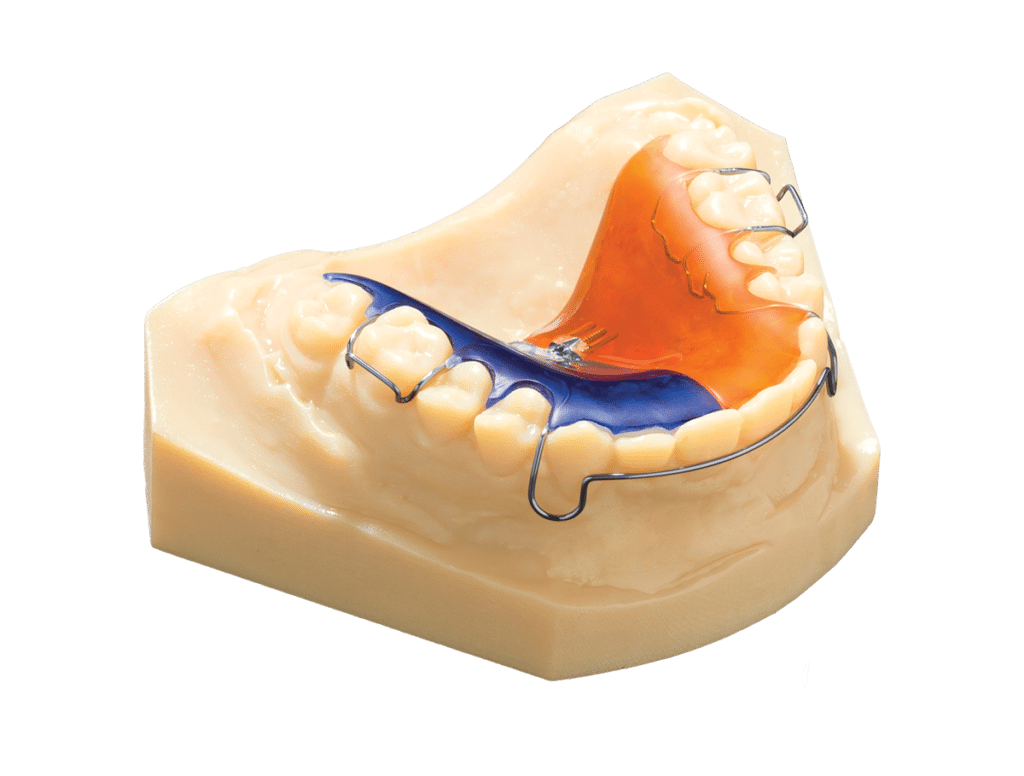

Go Digital and 3D Print It

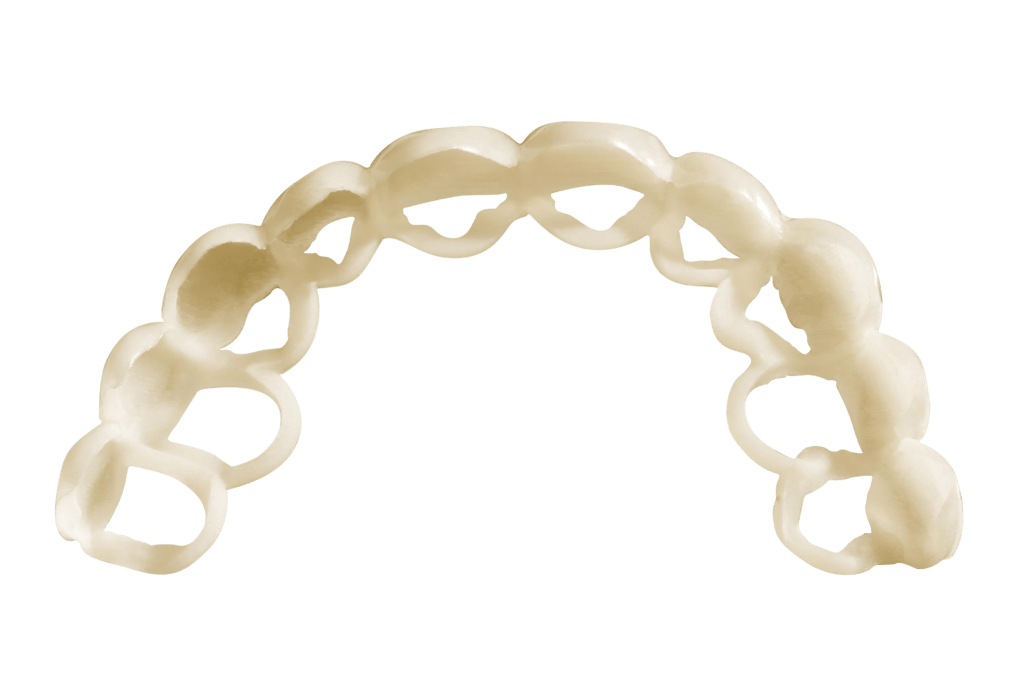

With PolyJet technology, the Objet Eden260VS Dental Advantage offers ultra fine, 16 micron, layer resolution. Take files from digital scans and use the Eden260VS’s four specialized materials to produce dental and orthodontic applications including: stone models, surgical guides, and veneer/denture try-ins.

Applications

Materials

Eden260VS Dental Advantage Specifications

Build Tray Size |

Build Tray Size255 x 255 x 200 mm (10.0 x 9.9 x 7.9 in) |

Minimum Layer Thickness (Z-axis) |

Minimum Layer Thickness (Z-axis)horizontal build layers as fine as 16 microns (0.0006 in) |

Build Resolution |

Build ResolutionX-axis: 600 dpiY-axis: 600 dpi Z-axis: 1600 dpi |

Model Materials |

Model MaterialsVeroDentPlus™ (MED690)VeroDent™ (MED670) VeroGlaze™ (MED620) Clear Bio-compatible (MED610) |

Support Materials |

Support MaterialsSUP705 (WaterJet removable)SUP 707 (soluble) |

Machine Dimensions |

Machine Dimensions870 x 735 x 1200 mm (34.25 x 28.9 x 47.25 in) |

Machine Weight |

Machine Weight254 kg (560 lbs) |

Workstation Compatability |

Workstation CompatabilityWindows 7 32/64-bit |

Network Connectivity |

Network ConnectivityLAN - TCP/IP |

Operating Conditions |

Operating ConditionsTemperature 18-25ºC (64-77ºF); relative humidity 30-70% |

Power Requirements |

Power Requirements110-240 VAC 50/60 Hz: 1.5KW single phase |

Regulatory Compliance |

Regulatory ComplianceCE, FCC |