PolyJet 3D Printing Technology

PolyJet technology is renowned for its outstanding realism and breathtaking aesthetics. The technology works similarly to traditional inkjet printing, but instead of jetting ink onto paper, a print head jets liquid photopolymers onto a build tray where each droplet cures in a flash of UV light.

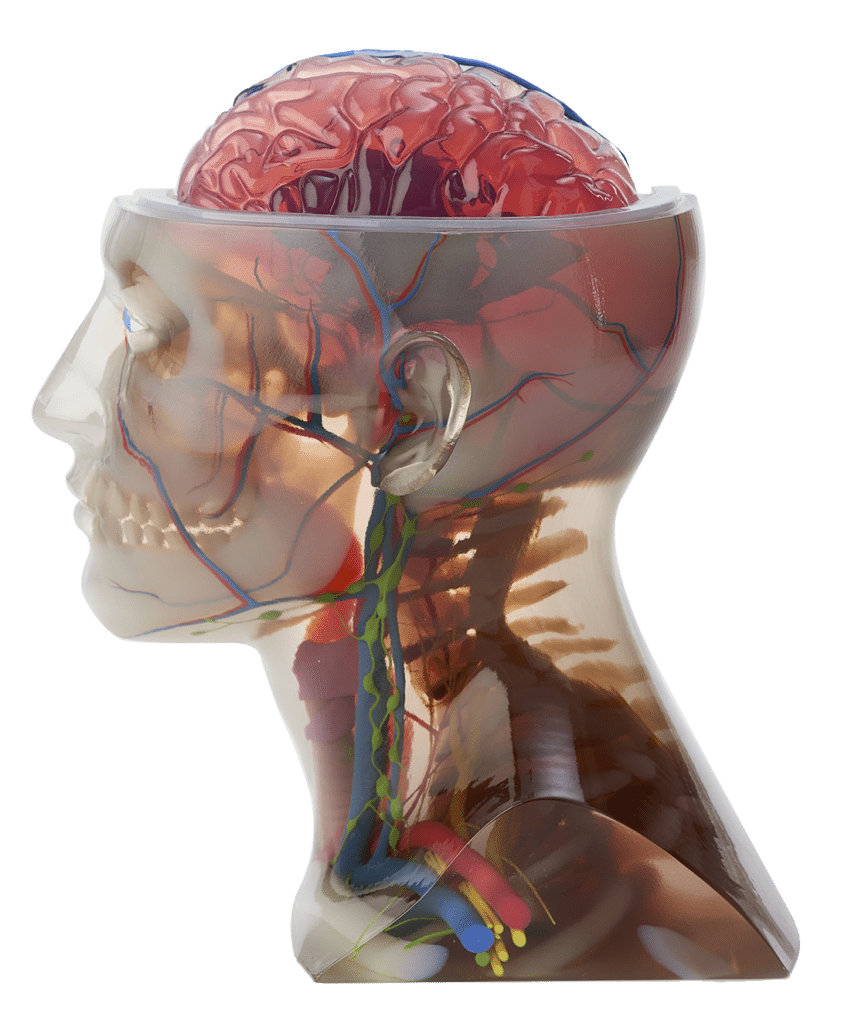

Every PolyJet 3D Printer offers sharp precision, smooth surfaces and ultra-fine details. And, by combining a variety of photopolymers in specific concentrations and microstructures the most sophisticated PolyJet systems can simulate everything from plastics and rubber to human tissue — and produce a full gamut of colors. You can now create prototypes, models, textures, and patterns that are incredibly detailed and with 1000s of material options to choose from you can incorporate diverse material properties and aesthetics.

Synonyms and similar technologies: multijet printing, photopolymer jetting

Multiple materials in a single print

High resolution down to 16-microns

Full-colour with overlays and textures

Over-mold without tooling

How Polyjet Works

Polyjet 3D printing technology works by jetting layers of curable liquid photopolymer onto a build tray.

- Pre-Processing: Preparation software determines the arrangement of photopolymers to be cured and support material from a native 3D CAD file automatically.

- Production: Polyjet printers instantly cure the droplets of liquid photopolymer using UV. Thin layers accrue onto the build tray to create the 3D part(s). Where support is needed, the printer will jet removable support material.

- Support Removal: Material is easily removable by hand, with water or in a solution bath. No post-curing is required as the 3D printed part is ready to handle straight off the build tray.

Advantages

Printed parts with Polyjet technology are smooth, polished and accurately detailed.

- Polished, smooth and detailed prototypes that simulate end use parts.

- Detailed and precise parts such as realistic teeth and gums, implant models, and even maxillofacial models

- Create complex shapes, intricate detail, and delicate features.

- Integrate a wide variety of materials and colors into individual models for unmatched efficiency.

PolyJet Technical Specifications

Maximum Accuracy |

Maximum Accuracy0.1-0.3 mm |

Layer Resolution |

Layer Resolution16 microns, or 0.016mm/0.0006"X/Y resolution of 0.0017 |

Minimum Wall Thickness |

Minimum Wall Thickness1mm |

Maximum Part Dimensions (Single Build) |

Maximum Part Dimensions (Single Build)490 x 390 x 200 mm (19.3 x 15.35 x 7.9 in.) |

Shore Hardness Ranges |

Shore Hardness Ranges27A - 95A |

Finishes |

Finishesmatte or glossy, additional finishes available as a service |

Polyjet 3D Printers

Desktop Design Series

Print small, precise models in a single material, right on your desktop.

-

Objet24

-

Objet30 Pro

-

Objet30

-

Objet30 Prime

Design Series

Gain efficiency and design freedom with more material options and hands-free support removal.

Production Series

Bring agility and aesthetics to every stage of product development with the widest range of colors and material properties for prototypes and tooling.